Artists Find Ways To Help During PPE Shortage

Big companies across Brooklyn are shifting to making face shields and other medical equipment to help with the shortages at NYC hospitals. Yesterday, Mayor Bill De Blasio applauded their efforts, which he said will greatly reduce the shortage in the city within the next month. “These are brand new production lines created from scratch by companies here, by New York City workers in an atmosphere crisis, and they’ve surpassed any possible expectation we could have, and they’re going farther,” he said during a press conference yesterday.

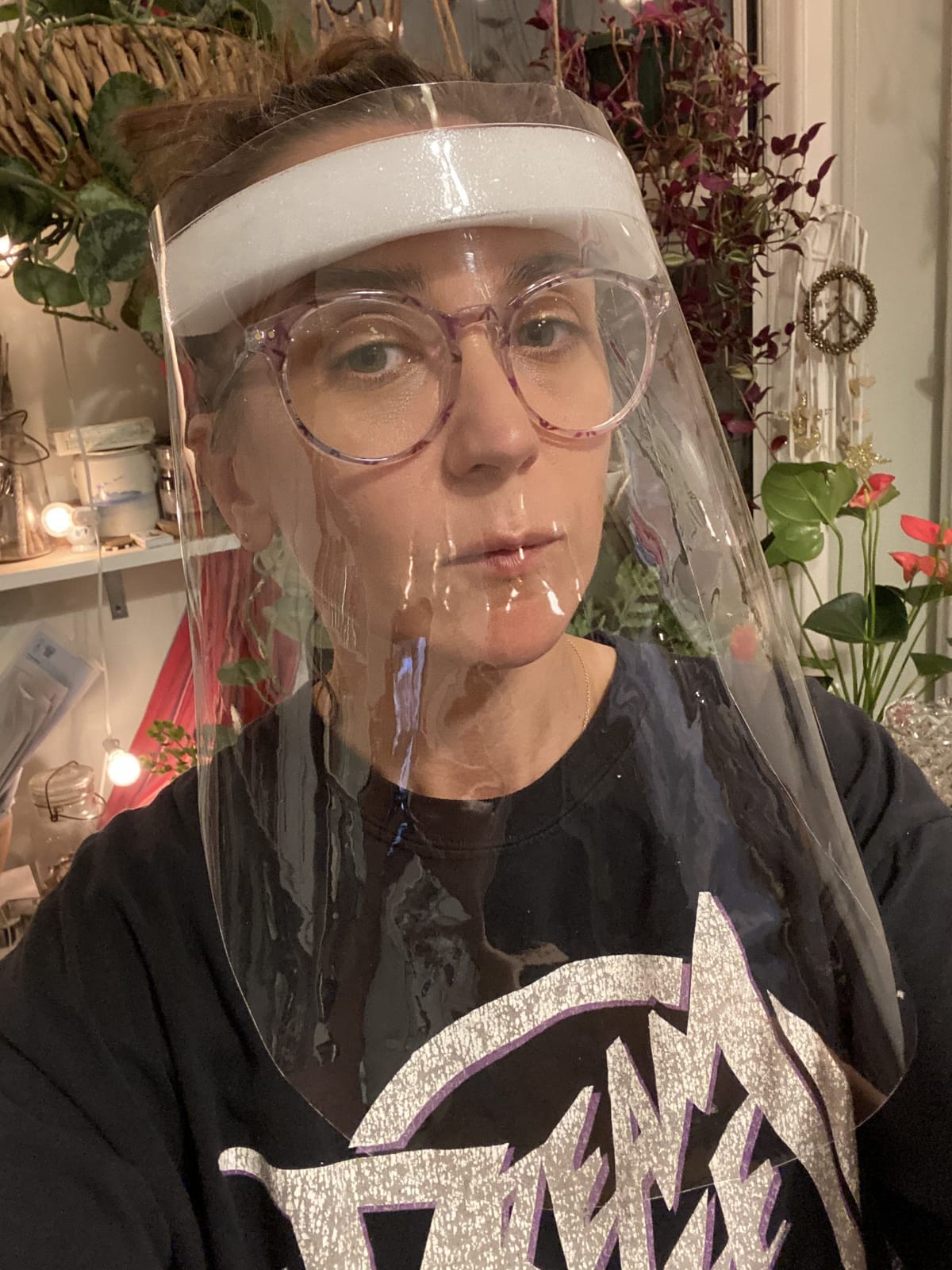

Freelancers and small businesses in the art community have stepped up to help in their own way, making personal protective equipment for medical staff on quick turnarounds, and in small batches.

ArtCube Nation is a group of people who ordinarily work in film, television, theater, and events creating sets and designs. They use the ArtCube Nation website as a place to share gigs, crowdsource advice, and share leftover materials.

“We help each other out in a jam,” said Eva Radke, CEO of ArtCube Nation, “which is a constant in the art department in film and television because everything is so funny and strange and it can be ludicrous. Like a jack-in-the-box that catches on fire. Someone has to build those crazy things.”

The coronavirus pandemic and subsequent shutdown left many of these artists unemployed. “No one’s working. No one has a job,” Radke said. But sitting around waiting for things to change wasn’t an option. As the city began to shut down in mid-March, Radke decided that she had to do something.

She wrote up a post asking for volunteers for a new ArtCube Army that would create personal protective equipment (PPE) for medical professionals in New York City. Radke blasted the post out to ArtCube Nation members, and about 120 people signed up to help. Those people recruited friends and neighbors. Most members are in Park Slope and Williamsburg, Radke said, and some of their small business members are based in the Navy Yard.

“We source all the materials, then we cut them into elements so they can be constructed by makers,” Radke said. They have already delivered over 2,000 face shields to SUNY Downstate Hospital, Health + Hospitals Kings County, Catholic Guardian Services, NYU Langone Health Brooklyn, Columbia Presbyterian ER and others.

Although they are small batches, Radke said that their quick-turnaround has been an advantage. “We’re guessing that 50 shields today are a lot better than 5,000 in three weeks,” she said.

Quick turnaround also allows the ArtCube Army to get feedback about the PPE right away.

“Like our first rounds that went out [a few weeks ago] – we’re like, ‘What did you think? How are they working? Are they effective, surgeons?’ And the feedback that we got was like, ‘My nose is too big.’ We’re like, no, our foam is too small.”

And so they changed their design for the next round of face shields to allow more nose room. They also changed their design once it became harder to find elastic. Radke said those constant tweaks are the kind of thing that her team of art department freelancers are used to.

“This niche industry is already primed to stand up and act. We already work under pressure with no sleep, under-resourced, with no room for error,” Radke said. “It is in our DNA to work under those conditions.”

Radke also noted that creating shields is a way to feel like they are helping during an overwhelming time. She said someone asked her why they are doing this, and her answer was, “Because we can. This is giving us control of our environment. Which I think is a big psychological thing for people who feel out of control. But makers have to make.”ArtCube Army is continuing to work on their next orders. They are fundraising on their GoFundMe page to keep taking more orders and reimburse makers who have been paying for materials out of pocket.